Quality + Services Everlasting Success Way

Quality + Services Everlasting Success Way

Biomass Briquetting Machine (Straw Briquetting Machine) takes agricultural and forestry biomass wastes such as the…

The biomass pellet machine mainly takes the pine ( pinus sylvestris, white pine), the bixa…

RDF (Refuse Derived Fuel) production process is as follows: firstly, mechanical method is used to…

Multifunctional pulverizer, also known as slimmer, can crush the sawdust, the wood chip, the waste…

Hebei Minghong New Energy Co., Ltd., holding the registered trademark “HMNEC”, is a complex company engaging in developing, manufacturing and sales of Biomass Briquetting Equipment and offering services thereon. The company’s main business includes: the manufacture and sales of biomass briquetting equipment, the development, application and sales of biomass briquette fuel.

Read More

Biomass Briquetting Machine (Straw Briquetting Machine) takes agricultural and forestry biomass wastes such as the cornstalk, the wheat straw, the rice straw, the peanut shell, the corn cob, the cotton pole, the soybean pole, the weed, the branch, the leave, the sawdust, the wood chip, the bark, etc as raw materials, and the raw materials become small lumps or bars of biomass molded fuel (BMF) or animal feed after crushing, compressing, densifying and forming.

The biomass pellet machine mainly takes the pine ( pinus sylvestris, white pine), the bixa orellana, the poplar, the eucalyptus and other forestry wastes as raw materials, and its material state can be trees, boards, barks, shavings, furniture factory wastes, and other styles. The materials need to be processed by crushing, drying, screening and other front-end processes, and then enter into the biomass pelletizer processing process of granulating, cooling, packaging, etc to make finished biomass pellets.

RDF (Refuse Derived Fuel) production process is as follows: firstly, mechanical method is used to classify the wastes. According to different material properties, the waste plastic, the waste paper, the wood chip, PVC and other flammable wastes are separated from the garbage, and formed into harmless lumps of fuel after screening, shredding, drying and briquetting. Because the RDF is extruded and solidified at high temperatures, it is sterilized during manufacturing and can be stored easily or shipped directly to a power plant to generate electricity.

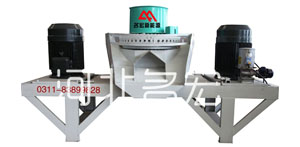

Multifunctional pulverizer, also known as slimmer, can crush the sawdust, the wood chip, the waste materials of the furniture factory, the cornstalk, the wheat straw, the cotton stalk, the peanut shell, the beanpole and other crop straws. The multifunctional crusher has the advantages of simple and firm structure, stable operation and good crushing effect. The crushed material can be directly discharged from the grinding chamber of the host machine, and the discharging size can be obtained by replacing the mesh screen with different apertures.

The shredder is a kind of machine used for fine shredding, generally used to deal with raw materials or leftover materials without processing, so that the materials can be finer in size. Typical examples are as follows: plastic or rubber leftover materials that are shredded are used as raw materials, then they are melted, pelletized and used to recreate plastic bottles, tires or trash cans, etc. The shredding machine is used in the plastic recycling industry, and often used in shredding and recycling of waste large diameter PE plastic pipes, pack plastic films in bales, stacks of plastic sheets, industrial…

Minghong pulverizer is mainly applicable for crushing the agricultural straw and stem such as the wheat straw, the corn stalk, the peanut vine, the haulm, the tobacco stalk, the cotton stalk, the bean pole, the forage grass, etc., and all kinds of branches, wood chips, plywood residues, wood wastes, etc. The machine is composed of main machine frame, cutting machine, feeding equipment, overload protection device. There is optimized simple clean design, high torsion forces, durable and stable performance, sharp and diversified configured knives which enables high pulverizing performance.

Wood crusher is mainly used to break log, timber and other wood products, so that these wood products can reach their highest value in use and make it possible to reduce environmental pollution. This crusher is a more efficient, ideal and affordable equipment for crushing wood. Its main crushing raw materials include the log fragment or slice, the peeled small-diameter wood, the bamboo wood, the slab, fragment or slice of the logged secondary firewood remainder, etc.

The baling machine is suitable for the compress packaging of loose materials, so that by reducing the volume, it is easy to package and transport and can reduces the storage space. It has the characteristics of compact in structure, strong and firm, economical and practical, use-friendly, safe and reliable, etc. Main objects to be baled are agricultural residues such as wheat straw, corn stalk, rice husk, etc., saw dusts, wood chips and other loose materials. It is widely accepted and used by farms, straw recycling firms and animal feed manufacturers.

The rice husk is a common waste material in rice factories. Because the rice husk is relatively light, which makes it occupy a large area and inconvenient to transport. Therefore, people need to use packaging machinery to compress and pack rice husk, so as to save storage space and make it facilitate to transport.

Rice husk baler The rice husk is a common waste material in rice factories. Because the rice husk is relatively light, which makes it occupy a large area and inconvenient to transport. Therefore, people need to use packaging machinery to compress and pack rice husk, so as to save storage space and make it facilitate to transport.

With intentions, first-class quality and professional services, HMNEC is willing to work with customers to create a wealth of tomorrow.

Address: Industrial Park, Tongye Town, Luquan District, Shijiazhuang City, Hebei Province, China

Chinese Website: www.zhongguominghong.com

English Website: www.hmneco.com

Tel: 86-18032903888, 86-17778220236

Email: hmnec@outlook.com, info@hmneco.com

2024-03-07 01:26:10