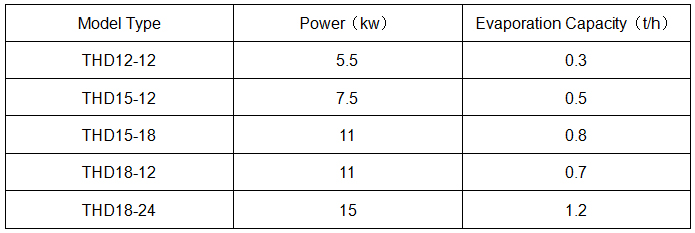

Technical parameters:

Product Description:

The drying process is required when the moisture content of the raw material exceeds the standard requirements. After drying, the raw material reaches the required standard moisture range. The rattler-drying machinery adopts low-speed rotation, bent board hammering and dispersing materials, so that it can mix high temperature airflow and materials and achieve the drying effect.

The rattler-drying machinery is widely used in food, feed, chemical, pharmaceutical, mining and other industries.

The working process of the equipment is as follows: after the dehydrated wet material is added to the dryer, the materials is evenly dispersed in the dryer and fully contacts with the hot air under the rotation of the shoveling plate device with uniform distribution in the drum, which speeds up the heat and mass transfer of drying. In the drying process, materials are discharged into finished products through the starry discharge valve in the other section of the dryer under the effect of inclining shoveling plates and hot air.

It is suitable for drying various dregs materials, such as the brewer’s grains, the bean dregs, the spray corn husk, the coal slim, the fruit residue, etc. It is also suitable for drying various biomass materials, such as the sawdust, the wood chip, the wood powder, the straw, the forage grass, the animal waste, etc. And the same goes for the industrial solid waste, the classified household waste, etc.

This equipment includes the dryer, air stove, cyclone dust collector, air shutter, blower, pipe, etc.