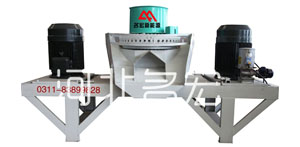

Operation skills of straw briquetting machine

Normally, the straw briquetting machine should first pays attention to the cleanliness and hygiene of the equipment, especially checking the automatic drain valve on the filter every day. Of course, in order to make the machine run better, special attention must be paid when replacing the tower and boosting the pressure. Before each use, it is necessary to check in advance. Of course, it is necessary to regularly check the operating conditions, inlet pressure, inlet temperature, and air flow rate of the equipment. Check whether the moisture indicator of the device is normal. Generally speaking, if the moisture indicator…