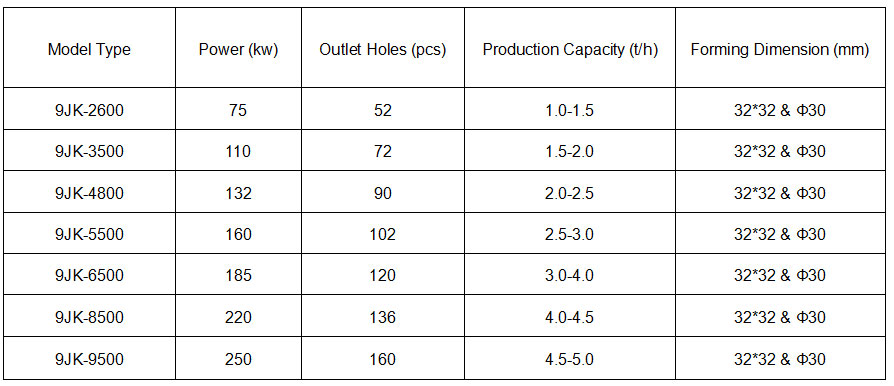

Product parameters:

Product Description:

RDF (Refuse Derived Fuel) production process is as follows: firstly, mechanical method is used to classify the waste. According to different material properties, the waste plastic, the waste paper, the wood chip, PVC and other flammable wastes are separated from the garbage, and formed into harmless lumps of fuel after screening, shredding, drying and briquetting.

Because the RDF is extruded and solidified at high temperatures, it is sterilized during manufacturing and can be stored easily or shipped directly to a power plant to generate electricity.

Formed RDF fuels is block in shape, the cross section of which is 30*30mm, the length of which is about 50mm, the moisture content of which is about 20%, and the calorific value of which is close to the coal. It can be widely used in waste power plants, cement plants, various industrial boilers, etc.

The disposal of the object:

General industrial solid waste range: the raw material is mainly the industrial leftover materials of shoe or garment factory, the paper-making scum produced during the production and processing of the paper mill, domestic waste, sludge, agricultural, forestry and industrial waste, etc. These materials have characteristics of low ash, high volatile and easy burning, etc, and they are low-value recyclable materials and can be effectively used in the coal-fired coupled power generation or solid waste power generation to realize recycling.